Enhancing Efficiency with Nut Weighing Filling Machines

In the fast-paced world of modern business, efficiency and precision are paramount. This is especially true in industries like food packaging, 3D printing, and accessories manufacturing, where the demand for quality and consistency drives the need for advanced technology. One such innovation that has revolutionized these sectors is the nut weighing filling machine.

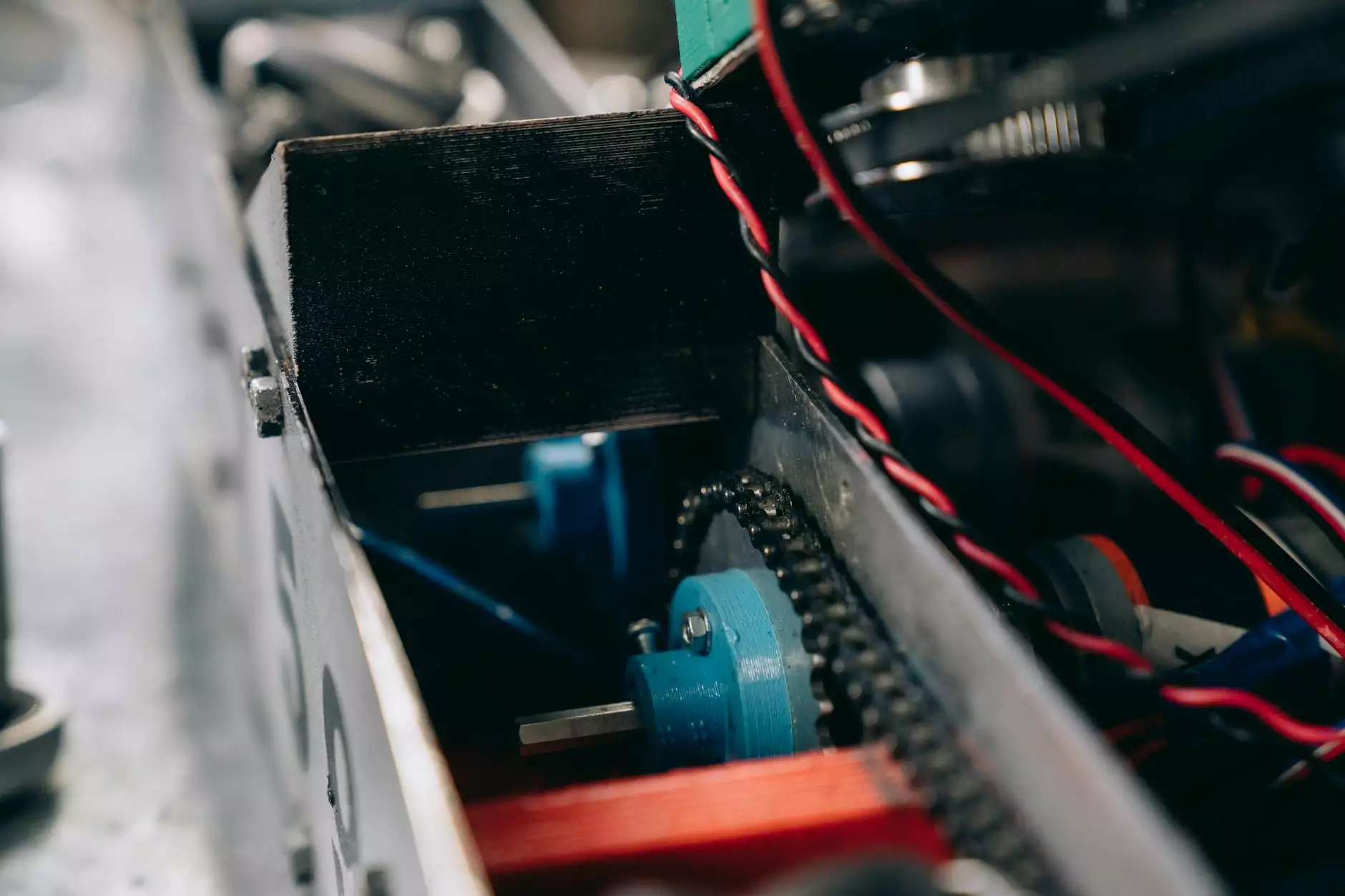

Understanding the Nut Weighing Filling Machine

A nut weighing filling machine is a specialized device designed to accurately measure and fill containers with nuts or similar products. This technology plays a crucial role in manufacturing and packaging processes by ensuring that the exact quantity of product is packed into each container, minimizing waste and maximizing efficiency.

Key Features of Nut Weighing Filling Machines

- Precision Weighing: The machines utilize advanced scales and sensors to ensure that the weight of the product filled meets the predetermined standards.

- Speed and Efficiency: With high-speed filling capabilities, these machines can significantly reduce the time taken for packaging, benefiting production lines.

- Versatile Applications: Ideal for a variety of nut types, including almonds, walnuts, cashews, and more, as well as other granular products.

- User-Friendly Interfaces: Many modern machines come equipped with intuitive controls, making it easy for operators to manage the filling process.

The Importance of Accuracy in the Food Industry

In the food production sector, accuracy is crucial. Ensuring each package contains the correct amount of product not only satisfies customer expectations but also complies with regulatory standards. Over-filled packages can result in product loss and increased costs, while under-filled packages may lead to customer dissatisfaction and potential legal issues.

The Role of Technology in Ensuring Accuracy

With advancements in technology, nut weighing filling machines now incorporate sophisticated measurement systems that provide real-time feedback. This allows for immediate adjustments to be made during the filling process, ensuring high levels of accuracy.

Benefits of Using Nut Weighing Filling Machines in Businesses

Incorporating a nut weighing filling machine offers numerous advantages to businesses, particularly within the accessories and 3D printing industries. Here are some core benefits:

- Increased Productivity: Automation reduces the need for manual labor, allowing companies to achieve higher output levels.

- Cost Savings: Reduced waste and improved product handling lead to lower operational costs.

- Consistency: Automated machines deliver uniformity in product weights, leading to a stronger brand reputation.

- Enhanced Safety: By minimizing manual handling, companies can create a safer work environment.

Types of Nut Weighing Filling Machines

The market offers various nut weighing filling machines, each designed to cater to specific business needs. Understanding these different types can help businesses choose the right equipment:

1. Linear Weighing Systems

These systems work by weighing product on a linear conveyor, filling bags or containers based on pre-set weights. They are ideal for businesses needing consistent filling for a wide range of small to medium-sized products.

2. Multi-Head Weighing Systems

Using multiple weigh hoppers, these machines can quickly and accurately provide the necessary weights for larger production runs. They are commonly used in high-volume environments, such as in food packaging.

3. Auger Filler Systems

Ideal for powdery substances and smaller nuts, these machines use an auger to dispense the product securely and accurately, ensuring that even fine materials are filled without spillage.

How to Choose the Right Nut Weighing Filling Machine

When selecting a nut weighing filling machine, businesses should consider the following factors:

- Product Type: Different machines cater to various nut types and sizes, so select one compatible with your products.

- Production Volume: Assess your daily throughput requirements to choose a machine that can handle your workload.

- Space Requirements: Ensure you have adequate space in your production facility to accommodate the machine.

- Budget: Evaluate your budget and consider both upfront costs and long-term savings through reduced waste and improved efficiency.

Integrating Nut Weighing Filling Machines into Your Business

Integrating a nut weighing filling machine into your existing production line can be a transformative process for your business. Here are some steps to ensure a smooth implementation:

1. Conduct a Needs Assessment

Evaluate your current packaging processes and identify the areas where a filling machine could improve efficiency and productivity. Determine the specific requirements of the nuts you’ll be filling.

2. Train Your Staff

Proper training is essential to maximize the benefits of your new machinery. Invest time in teaching your employees how to operate, maintain, and troubleshoot the nut weighing filling machine.

3. Monitor Performance

After the implementation, continuously monitor the machine's performance to ensure it meets your expectations. Regularly maintain the equipment to prolong its lifespan and effectiveness.

The Future of Nut Weighing Filling Machines

As technology continues to evolve, nut weighing filling machines are set to become even more sophisticated. Innovations such as IoT (Internet of Things) integration will enable real-time monitoring and data analysis, allowing businesses to optimize their production processes proactively.

Embracing Automation and Intelligent Systems

Automation and intelligent systems will not only enhance accuracy but will also allow for more flexible production lines. Machines will adapt to varying product types and changing market demands with minimal downtime.

Conclusion

Investing in a nut weighing filling machine can prove to be a game-changer for businesses in the accessories and 3D printing sectors. The combination of increased accuracy, efficiency, and reduced operational costs makes these machines an invaluable asset. By embracing this technology, businesses can stay competitive, meet customer demands, and pave the way for future growth.

For more information on the benefits and features of nut weighing filling machines, or to explore our range of products tailored to your business needs, visit shinebenmach.com.